Digital Transformation in Manufacturing: Importance and Digital Solutions for Businesses

I. What is Digital Transformation in Manufacturing?

Digital transformation in production is understood as the process of applying digital technologies and in overall activities to improve efficiency and open up new development directions based on the application of technology.

Digital transformation is common around the world and is also receiving special attention and attention from Vietnam.

In production, because domestic labor is still quite cheap and the budget for digital transformation has not been paid enough attention, businesses often lack interest in this.

However, digital transformation is one of the inevitable things when society is more and more developed. If businesses do not keep up, they will soon be left behind in the increasingly fierce race.

II. The importance of digital transformation in industrial production

2.1. Increase the ability to scale the business

Any business is aiming to reach out and expand, even with pure businesses in the manufacturing sector.

However, there are many limits to the old-fashioned way of working and manufacturing such as accuracy, health limits, and worker endurance.

The digital transformation with modern technologies opens up many new directions of the manufacturing industry, providing a long-term direction on the upcoming path.

2.2. Improve product quality

Digital transformation allows machines to participate more in the production process, greatly reducing errors.

With the advancements in AI as well as robotic technology, letting machines do the jobs that need high precision is an inevitable trend to help improve product quality and reduce costs.

2.3. Smart cost optimization

Production costs affect not only the price of products when they reach consumers, but also determine the profitability and competitive advantage of businesses.

Digital transformation allows all data to be displayed in digital form, making it easier for businesses to evaluate inefficiencies for better optimization.

2.4. Speed up delivery

The entire system of ordering, inventorying, linking with shipping units and buyers is now supported with digital conversion to help shorten the delay time for orders.

Not only that, the inventory systems, calculating the number of inventory orders are also extremely effective

2.5. Ensure safety in production

The replacement of machines in dangerous stages minimizes the risks that may happen to workers. To achieve this, digital transformation plays an indispensable and mandatory role.

III. Technology solutions for digital transformation of the manufacturing industry

There are many solutions to digital transformation of manufacturing industries, but there are 4 common solutions that are often focused on:

3.1. Automation and robotics

Automation and robotics aim to transfer all or most of the work to machines.

This is something that many businesses have done to increase the accuracy and quality of products as well as reduce labor costs a lot.

Automation and robotics will give businesses the ability to work non-stop with almost zero error.

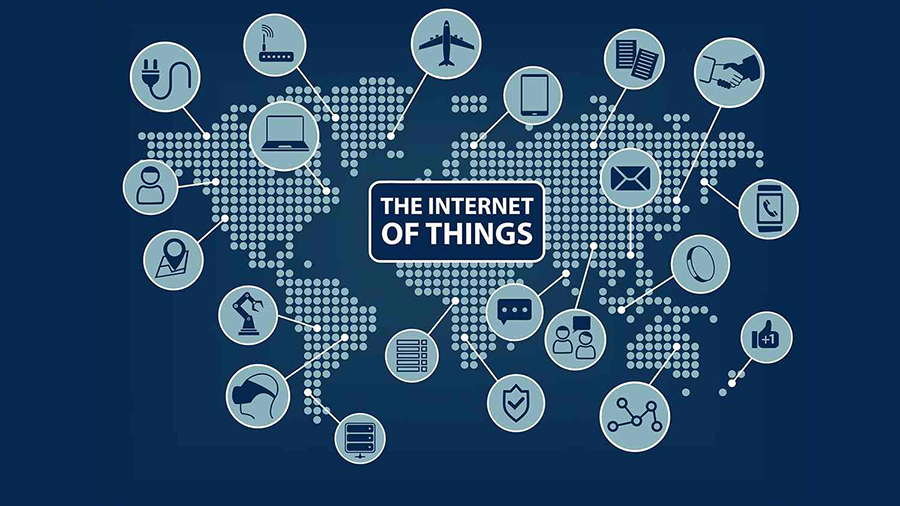

3.2. Internet of things

Internet of things (IOT) or roughly understood as a system of things connected through a network. This is a network where all devices are connected via the internet, allowing people to command and control things from a long distance.

The special thing about the Internet of things is that it completely breaks down geographical barriers with almost instant response thanks to the advancement of network technology.

3.3. Big data

Big data is a huge block of data stored in the form of information, collected from every possible activity.

As a result, the computer can analyze and make in-depth assessments, serving the assessment and making future-oriented predictions.

Big data can also be applied to many other areas of the business to help overcome weaknesses and increase work efficiency.

3.4. Smart Factory

Smart Factory is a relatively complicated concept, but you can understand it as a combination of information technology (IT) and operation technology.

Smart Factory allows all parts of the business, from the management board, sales apparatus, factory... to interact in a clear, simple and effective way.

This technology will give businesses the ability to speed up expansion, control quality, optimize costs, etc., and comprehensively improve the efficiency of all departments.

IV. Consulting unit for digital transformation in industrial production

CMC TS is one of the leading units in the field of digital transformation for businesses. We provide total information technology solutions and services for your business.

With in-depth experience, CMC TS has helped many businesses to successfully improve and transform digitally, bringing outstanding efficiency and opening up more long-term development orientations.

One of our typical partners can be mentioned Hoa Phat Group with a digital roadmap to comprehensively change the company's operations, bringing great efficiency.

Digital transformation in manufacturing is an inevitable and irreversible trend. Faster businesses will have an outstanding advantage over competitors, opening up many long-term development directions. To learn more about CMC TS as well as our services, you can refer to:https://cmcts.com.vn/